HDPE Pipes for Sprinkler (Agriculture)

Price 500.0 INR/ unit

HDPE Pipes for Sprinkler (Agriculture) Specification

- Feature

- Corrosion resistant, UV stabilized, light weight, leak proof joints

- Pressure

- 2.5 to 6 kg/cm

- Application

- Sprinkler irrigation, agriculture water supply

- Life Span

- 50 years

- Product Type

- HDPE Pipes for Sprinkler (Agriculture)

- Material

- High-Density Polyethylene (HDPE)

- Shape

- Round

- Standard

- IS 16098 PART II & IS 16205/14930

- Connection Type

- Coupler, push fit, or flange joint

- Length

- Up to 6 m or as per requirement

- Thickness

- Pressure-rated as per standard; typically 2.5 mm to 8 mm

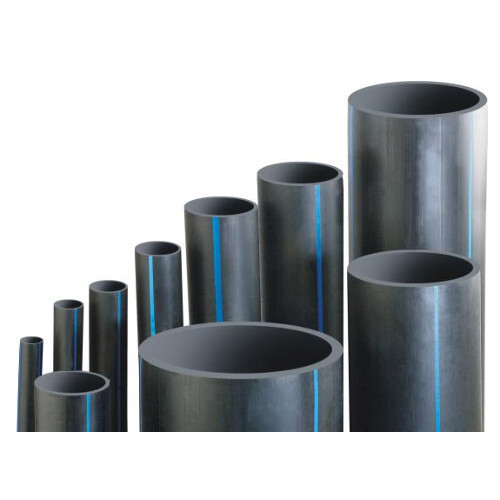

- Diameter

- 63 mm to 110 mm

- Weight

- Varies according to diameter and thickness

- Color

- Black with blue/green stripes

- Joint Type

- Quick coupling, fusion welded

- Tensile Strength

- 23-28 MPa

- Temperature Range

- -40°C to +80°C

- Flow Rate

- Optimized for high-flow irrigation systems

- Density

- 0.941 g/cm³

- Installation

- Easy to install, portable and flexible

- Resistant To

- Chemicals, abrasion, biological growth

- Wall Type

- Single/Double wall

- Usage Area

- Open fields, greenhouses, horticulture, landscape

- Burst Pressure

- Up to 10 kg/cm²

- Surface Finish

- Smooth internal and external surface

HDPE Pipes for Sprinkler (Agriculture) Trade Information

- Minimum Order Quantity

- 2000 unit

- Supply Ability

- 10000 Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About HDPE Pipes for Sprinkler (Agriculture)

DWC PIPES, which indicates that the company manufactures Double Wall Corrugated (DWC) pipes. Manufactures Double Wall Corrugated (DWC) pipes. Keshav Kripa Polyplast Products clearly states that they manufacture DWC pipes. Keshav Kripa Polyplast Pipes is a manufacturer of DWC pipes, they are a leading DWC pipe manufacturer in Kishangarh Ajmer . Double Wall Corrugated Pipes Supplier, DWC Pipe Wholesaler in Kishangarh Ajmer Rajasthan.

HDPE Pipes for Sprinkler (Agriculture).

|

Technical Details

![]()

Key Features

-

Manufactured as per TEC (Telecommunication Engineering Centre) specifications

-

Co-extruded inner lubricated lining ensures low friction for smooth cable blowing

-

High impact strength & crush resistance

-

UV stabilized & weather resistant

-

Lightweight, flexible & durable

-

Available in various sizes & colors with strip marking for easy identification

Applications

-

Telecom cable ducting (Optical Fiber Cables, Copper cables)

-

Electrical cable protection

-

Broadband & internet networks

-

Railway & highway communication projects

-

Underground and over-ground cable installations

Advantages

-

Faster & safer cable installation

-

Longer service life compared to conventional ducts

-

Cost-effective and maintenance-free

-

Suitable for all terrains rocky, sandy, or urban infrastructure

Ideal for Modern Irrigation Systems

These HDPE pipes are tailored to meet the demands of modern agricultural irrigation. Thanks to their optimized flow rate and quick coupling or fusion-welded joints, farmers can efficiently irrigate open fields, greenhouses, and horticultural setups. The pipes are portable and easy to install, perfectly suited for rapidly evolving irrigation landscapes.

Engineered for Durability and Safety

Constructed from HDPE material, these pipes exhibit robust tensile strength (2328 MPa) and high resistance to chemicals, abrasion, and biological growth. The smooth internal and external finish minimizes friction loss, while UV stabilization ensures long life even under direct sunlight. With proper installation, the pipes can serve reliably for up to 50 years.

Flexible and Standard-Compliant Design

The pipes accommodate diverse agricultural setups with single or double wall options, pressure ratings from 2.5 to 6 kg/cm, and diameters ranging from 63 mm to 110 mm. Manufactured as per IS 16098 PART II & IS 16205/14930 standards, they guarantee consistent quality and compatibility with widely-used sprinkler and irrigation systems in India.

FAQs of HDPE Pipes for Sprinkler (Agriculture):

Q: How are HDPE pipes for sprinkler irrigation installed on-site?

A: HDPE pipes can be installed using quick coupling, fusion welding, coupler, push fit, or flange joints. Their lightweight structure and flexible design make handling and laying easy, especially in open fields and greenhouses.Q: What are the main benefits of using these pipes in agricultural irrigation?

A: These pipes offer corrosion resistance, resistance to chemicals and abrasion, UV stability, lightweight construction, leak-proof joints, and optimized flow rateresulting in reliable, low-maintenance, and long-lasting performance.Q: Where are HDPE sprinkler pipes commonly used?

A: They are widely used in open fields, greenhouses, horticultural plots, and landscaped areas for sprinkler irrigation and agriculture water supply, supporting efficient and uniform watering.Q: What is the expected service life and pressure capability of these pipes?

A: With proper installation and usage, the pipes can last up to 50 years. They are pressure-rated from 2.5 to 6 kg/cm and can withstand burst pressures of up to 10 kg/cm, suitable for high-flow irrigation systems.Q: When should I consider choosing HDPE pipes over other materials?

A: HDPE pipes are ideal when you need a corrosion-resistant, chemically inert, flexible, durable, and easy-to-install irrigation solution that complies with agricultural standards and performs well in varying temperatures.Q: What process ensures the pipes remain leak proof?

A: Precision quick coupling and fusion welded joints, as well as high-quality push-fit or flange connections, prevent leaks. The smooth internal surface further reduces the likelihood of blockages and leakage.Q: How does the wall thickness and diameter affect usage?

A: The diameter (63110 mm) and wall thickness (typically 2.58 mm) are selected based on irrigation pressure requirements and flow rate, ensuring the pipes match system needs as per agricultural standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipes Category

HDPE Water Pipe

Minimum Order Quantity : 400

Color : Black with Blue Strips

Material : HDPE

Length : 6m, 12m or as required

Life Span : 50 years

High-Density Polyethylene (HDPE) Pipes

Price 1700.0 INR / Meter

Minimum Order Quantity : 400

Color : black

Material : HDPE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free