Cable Ducting

Cable Ducting Specification

- Tolerance

- Dimensional tolerance as per industry standards +/- 2%.

- Application

- Used for routing and protection of electrical cables in residential, commercial, and industrial installations.

- End Protector

- Provided at both ends to avoid sharp edges and enhance safety.

- Product Type

- Cable Ducting

- Type

- Rigid PVC Conduit

- Connection

- Push-fit or solvent weld joints.

- Diameter

- 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, and custom sizes available.

- Thickness

- 1.2 mm to 2.5 mm depending on diameter.

- Length

- 3 meters (standard) and custom lengths on request.

- Color

- White, Black, and Grey options available.

Cable Ducting Trade Information

- Minimum Order Quantity

- 2000 Meters

- Supply Ability

- 10000 Meters Per Month

- Delivery Time

- Days

About Cable Ducting

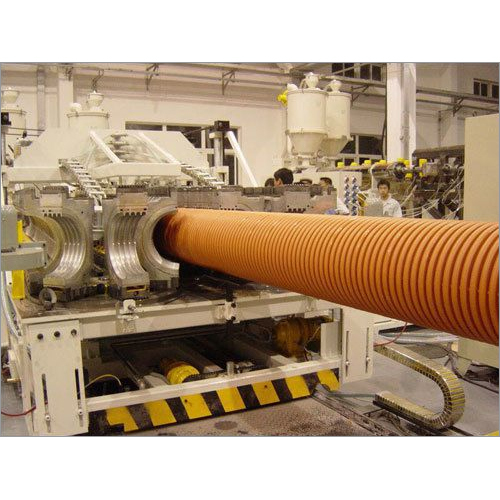

Cable Ducting is protective casing which is made up of high quality plastic materials which helps to protect the electrical wirings from the damages due to moisture, water and chemicals. Premium grade high density poly ethylene materials are used for the manufacturing of this insulated materials. It is available in many different sizes as per the diameter and length. Buyers can get this top quality materials from us in bulk at a reasonable price. DWC HDPE Corrugated Pipe, which is the same as double wall corrugated (dwc) pipes, indicating that the company manufactures them. Keshav Kripa Polyplast a Prominent & Leading Manufacturer of HDPE DWC pipes, Double Wall Corrugated Pipes, and Red Double Wall Corrugated HDPE Pipe. This confirms that they manufacture DWC pipes. manufacture Double Wall Corrugated (DWC) pipes and fittings, as seen on their DWC Pipes & Fittings product.Superior Material and Safety Standards

Manufactured from unplasticized polyvinyl chloride (uPVC), our cable ducting is not only fire-retardant and self-extinguishing but also resistant to corrosion, acids, and alkalis. With dimensional tolerance as per industry norms, each length conforms to IS 16098 PART II & IS 16205/14930, providing trusted reliability in critical applications.

Installation Flexibility and Protection

Designed with both push-fit and solvent weld connections, installation is straightforward for professionals and DIY solutions. Each conduit comes with end protectors to prevent sharp-edge hazards, maintaining safe handling and enhanced cable protection during and after installation.

Adaptability for Diverse Applications

Our round uPVC cable ducts are available in various diameters and lengths, including customizable options to suit unique project demands. Offered in white, black, and grey, they seamlessly integrate within residential, commercial, and industrial settings while maintaining structural integrity outdoors thanks to UV stability.

FAQs of Cable Ducting:

Q: How can I install uPVC cable ducting in different environments?

A: uPVC cable ducting can be installed on surfaces or concealed within walls and floors. Its lightweight construction and push-fit or solvent weld joints simplify installation, making it adaptable to residential, commercial, and industrial electrical setups.Q: What are the benefits of using uPVC cable ducting for electrical cable protection?

A: Using uPVC cable ducting ensures safe and reliable electrical cable management. It offers high impact resistance, superior electrical insulation, fire-retardant properties, and protection against corrosion and UV radiation, prolonging cable life and safety.Q: When should I consider using fire-resistant cable ducting solutions?

A: Fire-resistant cable ducting is essential in environments where safety concerns are paramount, such as industrial, commercial, or residential areas with high electrical loads. Self-extinguishing features minimize fire risks during unexpected short circuits or external ignition sources.Q: Where can custom sizes and color options for cable ducting be requested?

A: Custom diameters, lengths, and color options like white, black, and grey can be requested directly from the manufacturer, exporter, or supplier. This ensures a tailored solution matching your projects technical and design needs.Q: What process ensures the cable ducting meets industry standards?

A: Each cable duct undergoes rigorous manufacturing and quality testing to comply with IS 16098 PART II & IS 16205/14930 standards. Lengths are marked with standard compliance and size, guaranteeing performance and regulatory adherence.Q: How does UV stability benefit outdoor cable ducting applications?

A: UV stabilized uPVC protects against long-term exposure to sunlight, preventing deterioration or loss of mechanical properties. This makes it highly suitable for outdoor installations in both commercial and residential electrical networks.Q: What is the typical application range of uPVC cable ducting supplied by manufacturers in India?

A: uPVC cable ducting from Indian producers is widely used across residential, commercial, and industrial installations to route and shield electrical cables, meeting diverse market requirements as an exporter, supplier, wholesaler, and trader.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DWC Pipes Category

DWC PIPE

Price 425.0 INR / Meter

Minimum Order Quantity : 2000 Meters

Diameter : 32 mm to 300 mm Millimeter (mm)

Standard : IS 16098 PART II & IS 16205/14930

Product Type : CORRUGATED HDPE PIPES

Color : Any

Double Wall Corrugated Pipe

Price 420.0 INR / Meter

Minimum Order Quantity : 2000 Meters

Diameter : 40 mm 500 mm Millimeter (mm)

Standard : IS 16098 PART II & IS 16205/14930

Product Type : CORRUGATED HDPE PIPES

Color : black

DWC Sewerage Pipe 100 MM TO 500 MM

Price 425 INR / Meter

Minimum Order Quantity : 2000 Meters

Diameter : 100 MM TO 500 MM Millimeter (mm)

Standard : IS 16098 PART II & IS 16205/14930

Product Type : CORRUGATED HDPE PIPES

Color : blue

DWC HDPE Corrugated Pipe 150 MM TO 500 MM

Minimum Order Quantity : 2000 Meters

Diameter : 40 Millimeter (mm)

Standard : IS 16098 PART II & IS 16205/14930

Product Type : CORRUGATED HDPE PIPES

Color : BLACK, ORANGE, YELLOW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS